3D printing and it’s characteristics

What is a 3D printing?

Simply it is additive layering of a melted material layer after layer from the bottom to the top. Imagine how to build a brick house. You start at ground and you can’t put brick out of thin air somewhere else but the already existing layer of bricks or any other kind of additional support. And 3D printing is basically the same thing.

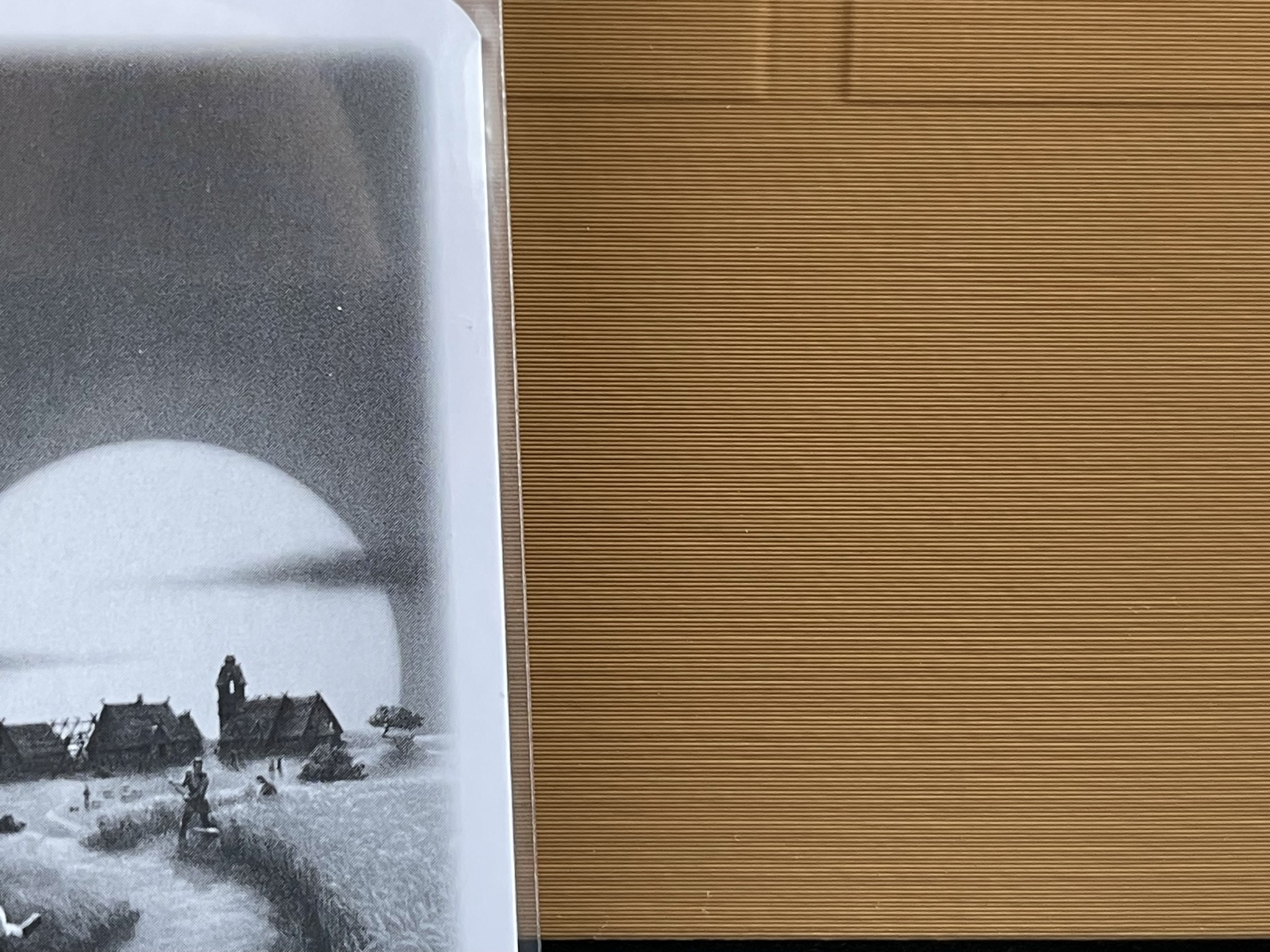

How does something printed look in detail?

Accuracy of a print is determined mostly from the height of a single layer. Considering we are talking here about insert for a board game the accuracy is the least thing to be bothered with. For example we are printing with hotends with diameter 0,4mm and one layer 0,3mm thick. Picture belows shows you the detail of layers and there is a familiar card to compare the size.

Is 3D printing relieable?

tl;dr: 3D printing is very reliable, but can consists variety of erros. These erros can be set to small and big ones.

A lot of things can go wrong during printing. It all starts with the quality of material which is used for printing. Cheap brands has low accuracy of filament diameter so the material delivery into the hotend of a printer can unstable.

Quality of printer is big topic too. We are relying, as a true patriots, on Czech and Wordwide number one, Prusa Printers. Although their printers can brake too, their support is so good that we can solve any issue in matter of hours or days.

Often forgotten topic is quality of a hotend itself. Used hotend can cause stringing - tiny strings made of filament when hotend moves from one spot to other with fast movement. Usual brass hotend prints nicely until it get worn off and that happens rather quickly. We are using hardened steel hotends which are for PETG material printing very good because they keep some heat out of the system basically eliminating the stringing.

Printing bed (the table on which you print the first layer) is an alchemy and we are very happy to use Prusa Printers who has the best beds on market. Using PETG is allowing us to use textured surface which adds to our insert characteristic bottom but also helps to hold product during printing good on the bed and after cooldown to easily remove it from the bed (heat, change of size, etc.).

Back to the material. Most of people are printing from PLA. This plastic is great that it dissolves faster, so its good for nature. What is not so great about the material is that it dissolves faster and products like that can be for trash only in two years or so since it gets fragile and some bigger force can brake it in pieces. UV light which is all around us is not helping the process too. PLA is basically hard to recycle since it can be recycled only in very sofisticated rafineries. Also printing with PLA has some issues as inner forces able to pull corners of boxes from the bed damaging the product beyond taste and repair.

That’s why we are printing from PETG which is rigid yet elastic, UV light does not harm it and it will stable even after years of use. On the other side printing from PETG is much more challanging and not so clean as from PLA. PETG has more tendencies to be stringy and “furry.” These furrs and strings can be cleansed with flame or hot air for example.

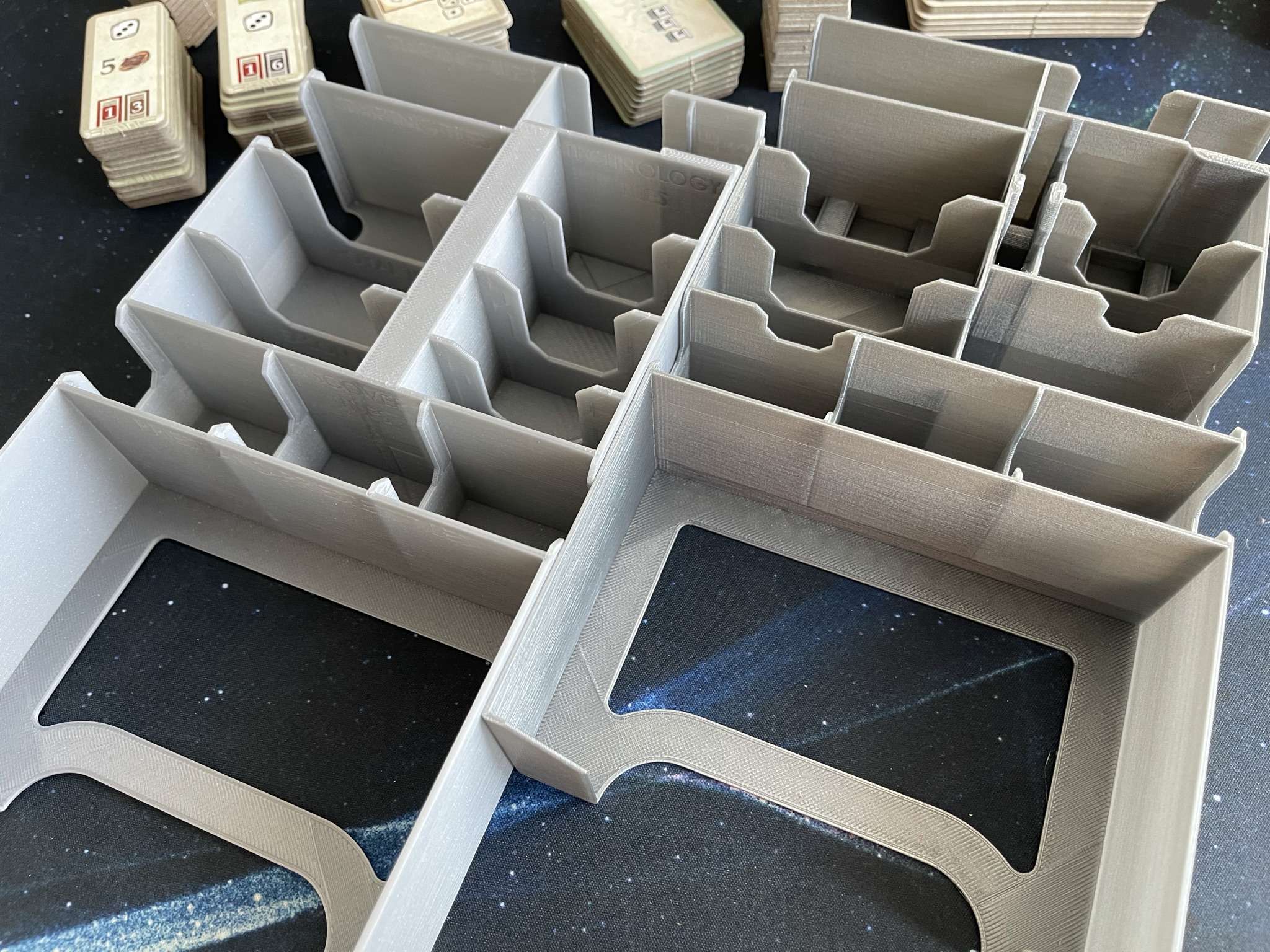

PLA on left vs. PETG on right

Strings on complex shaped models

Bigger issue is “honeycombing” on hotend and which eventually makes a drops. These drops eventually grow bigger until they fall of from hotend into the printed product. And sometimes it can affect the product. Drops which will fall simply on surface can be easily detached and makes maybe small “burn” spot which is a small error with no impact. Drops which hits the wall can be an issue voiding the quality of product and product like that will not get in your hands. Other usual error is when hotend moves from end of one layer to start a new one and material flow is not hundred percent under control in that moment so there can be a tiny gap or fray. Gap is barely visible and fray can be burnt by flame.

Erros from layer changes and burned drop (yellow)

Big error ending the product in recycle bin

What happends with small error products?

Since it usually is some form of burn or bubble in the middle of wall product like this is perfectly ok for final customer. You will never get those eye beating issues in your hands, they will end up in recycle.